|

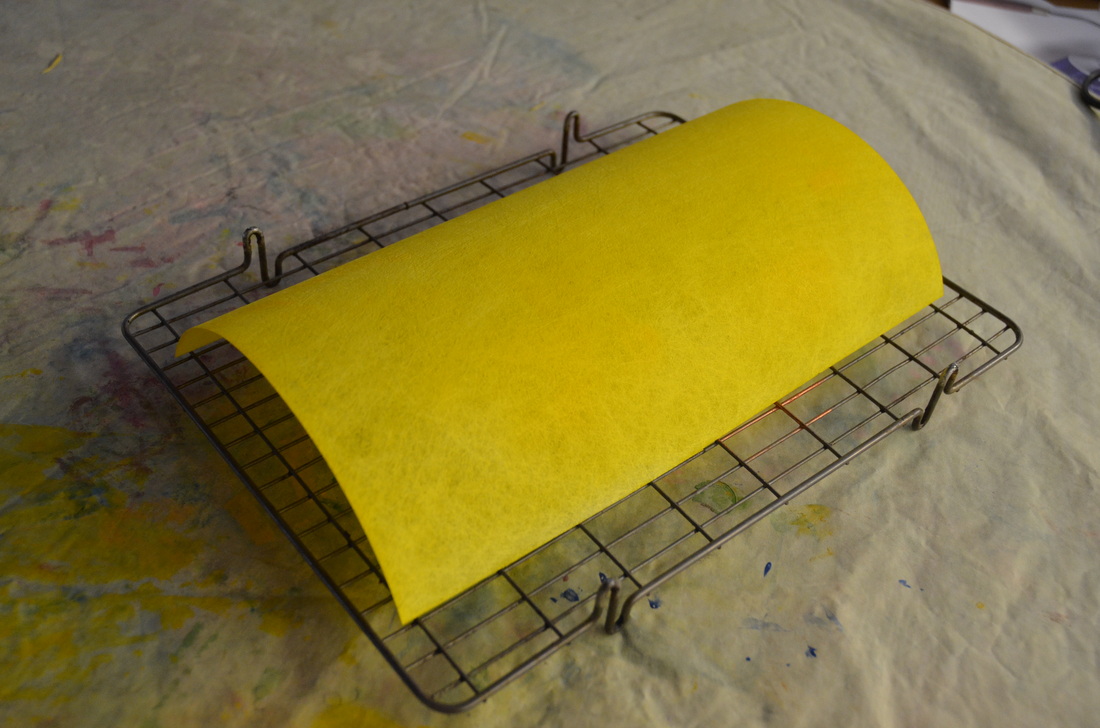

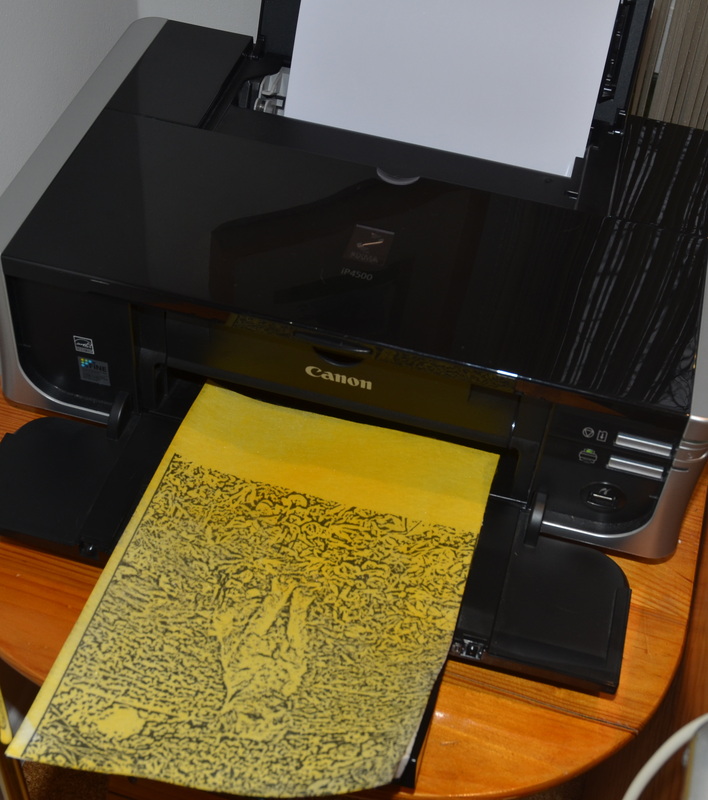

It has been a long time since I posted anything, mostly because I've been working flat out on the book. Well, the book is almost done. All the text has been written, the artwork is nearly completed, and Jane has just about finished laying out all the pages. It's hard to believe, but within a week or so, this book will be out of my hands, and not a moment too soon! This butterfly was done for the section on synthetic materials. First, I painted a sheet of medium weight Lutradur yellow, and let it dry. Then I treated it with Bubble Jet Set solution and hung it to dry. When that was fully dry, I ran the sheet of Lutradur through my computer so that a butterfly design printed straight onto it (in this photo, I have printed my dog Jack's image, but the butterfly was done the same way). Because of the stiffness of Lutradur, I didn't have to secure it to freezer paper before printing, it just went through the printer beautifully. Next I layered an orange synthetic organza over the top of the butterfly (I could see the printed design through it). I put a thick orange furnishing fabric underneath. After pinning the layers together, I thread painted the butterfly using a variegated orange/yellow/red thread (more on thread painting in my next post). After the butterfly was thread painted I used a heat gun to distress the organza and Lutradur. You can see the areas within the wings and along the edges that are melted. I will probably mount this on fabric covered foam board so it can be hung.

4 Comments

I had a wonderful private workshop with Kate Crossley last week http://www.katecrossley.com/ She taught me how to do acid etching. We started with a piece of cotton fabric that she had already machine embroidered and corded with polyester threads (which are not affected by the acid). We then layered the embroidered fabric with lots of other fabrics, placing the strips perpendicular to the embroidery on the base. We used cellulose, protein and synthetic fibers. When satisfied with the placement, we pinned the layers together. We then machine embroidered the pieces so the stitches were perpendicular to the first set of stitches using polyester thread. We applied a product called Fiber Etch at random on the layered, embroidered fabric, rubbing the gel into the fibers with the nozzle. Fiber Etch contains sodium bisulphate which eats away cellulose fibers (cotton, linen, rayon), but does not affect synthetics or protein fibers such as silk and wool; this is why polyester thread was used for the stitching. We dried the Fiber Etch gel with a hair dryer (windows open, wearing a mask!), then the piece was placed between two layers of baking parchment and pressed thoroughly, with the iron on a wool setting. The etched areas turned a coffee brown color. We rinsed the fabric under running water, scraping away the etched fibers. This is the result. It looks almost ethereal to me. Acid etching is a really fun technique with unpredictable results. Take a look at Kate's acid etched pieces on her website. She is available to teach workshops on this technique to groups.

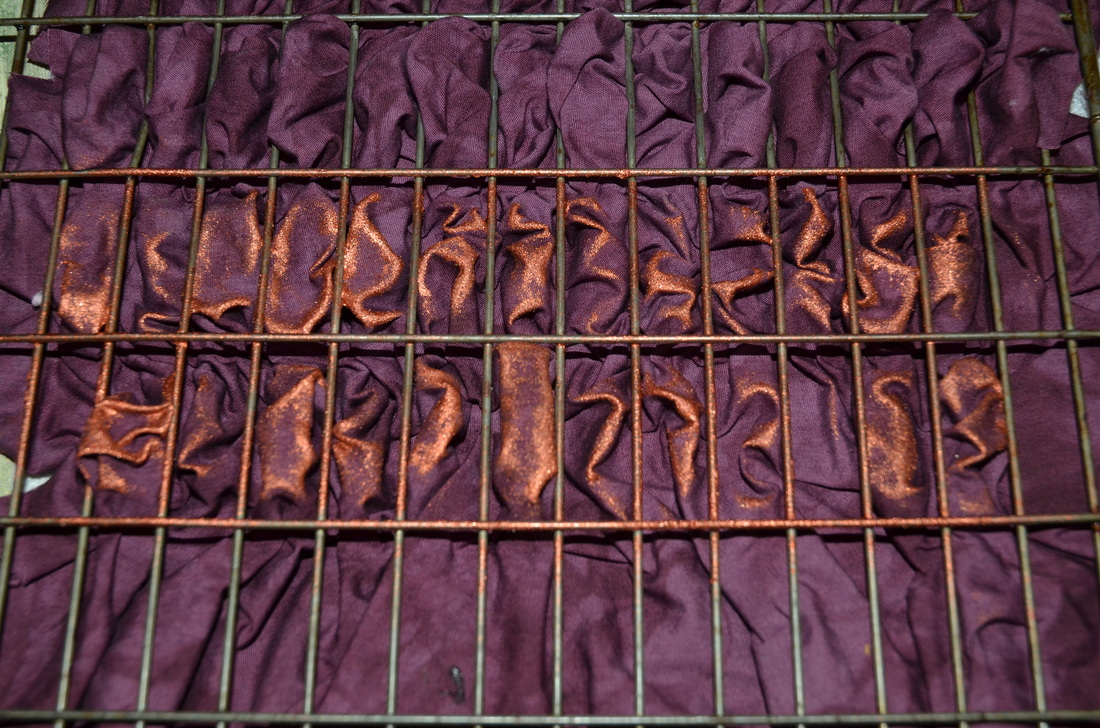

Following on from my last texture experiment, this time I am puff texturing, using hand-dyed fabric and a metal grill from my oven. To start, I wet the fabric thoroughly, then wrung it out so it was still damp. I placed the fabric on the grill, and using the eraser end of a pencil, began to poke the fabric in between the wires. It's important to hold the fabric in place as you do this so you don't pull up the bits that you pushed down previously - you have to practice with this as it can be frustrating! This is what it looks like when all the bits have been pushed through the wires. Next, cut a piece of lightweight fusible interfacing and press it on the fabric which is still tucked into the metal grill. (By the way, I'm wearing a bandage on my left hand as I had recently had a carpal tunnel operation - you don't have to wear gloves for this process!) If you wish, you can decorate the puffed areas before removing the fabric from the grill. Turn the grill over. Pour some fabric paint into a tray and roll a foam roller in it until the roller is coated. Then gently glide the roller over the puffed areas. I used a metallic copper paint here. You can see how it's just picked up some of the puffed areas. I then poured some deColourant into a tray and rolled another foam roller in that until it was coated. This photo shows rolling the deColourant on the fabric. deColourant is a discharge paste that will remove the dye from the fabric using heat and steam. Below is a close-up showing how the deColourant looks before heating. I allowed the fabric paint and the deColourant to dry overnight, then gently pulled the puffed fabric off the grill - the puffs are held in place by the fusible interfacing. I hovered a hot steam iron over the area coated with the discharge paste, moving it around until the fabric had discharged and turned whitish, but not pressing down on the puffs. If you look at the top photo of this post, you can see the white discharged areas on the right side. I could have left the fabric that way and used it for patchwork or applique, but I decided to pull off the fusible web and press the fabric flat to see what it looked like. Here's the result showing the discharged areas. I quite like the squiggles and will have fun using this in a future project. You could also press the fabric flat without removing the interfacing for a flattened textured effect.

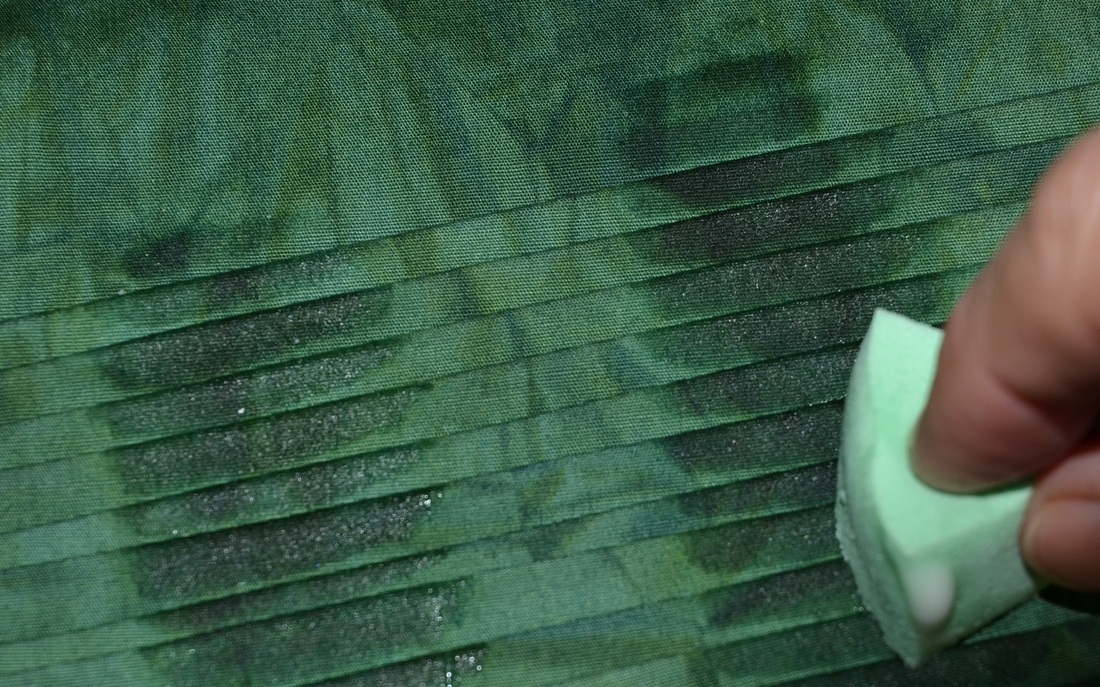

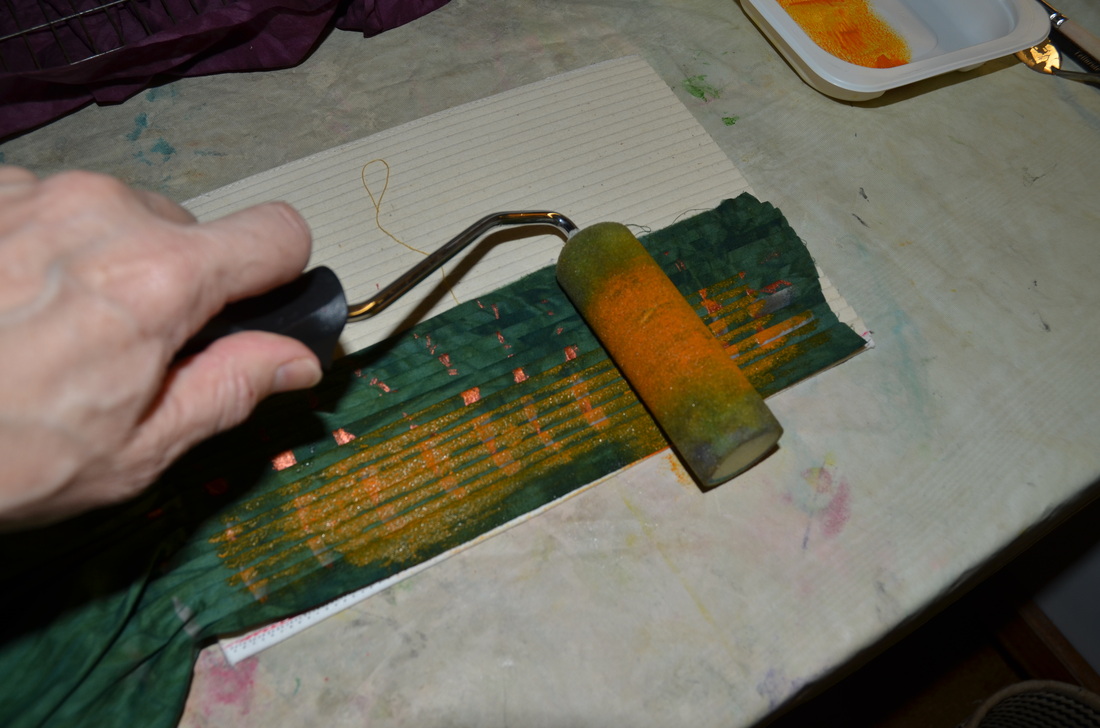

By the way, if you decide to work with the puff textured fabric in 3D (without flattening it as I did), use a sewing machine to stay-stitch just inside the area you are planning to cut so that you don't lose the puffiness; be sure to leave a 1/4"/6mm seam allowance for patchwork or if you are planning to turn the edges under for an applique. This week I have been texturing fabric so I can create "art references" for Tom (the artist of my book) to draw. It's also a great way to remind myself how to do the techniques so I can write the instructions more clearly. Here I am pleating some hand-dyed fabric using a purchased pleater. First press the fabric to remove all the wrinkles. Starting at the bottom edge, push the fabric into each pleat with your fingers as in the photo below. If you want to make larger pleats you can skip a few spaces, but I like the look of narrow pleats. It's a good idea to press the pleats every couple of rows as you work, just to keep them in place. Once I had made enough pleats, I applied some discharge paste to the fabric with a sponge to see what would happen. I drew some lines in the discharge paste with Markal paintstiks. I then applied metallic copper textile paint to the pleats using a brush (the X). I dipped my favourite Colouricious stamps in the paint and made a couple of stamps (snails on the right). When the paint and discharge paste were dry, I steam-pressed the fabric to discharge the colour. Then I removed the pleated fabric carefully from the pleater. You can see the grayish-white areas on the right where the fabric has discharged. Here is the fabric unpleated and pressed. A bit dull, but quite fun the way the design has broken up. So, to liven things up, I decided to re-pleat the fabric but in the opposite direction. I used a foam roller to apply a layer of yellow DeColourant Plus to the fabric (this is a discharge paste with a textile colour added to it, so that when the fabric is discharged, the white area is replaced with that colour). I also daubed on some dots with pale green textile paint and a brush. Here is the finished result, unpleated and pressed, making a very irregular plaid design. Not exactly a failed experiment, but it will look better when it's cut up for patchwork, I think! Next time, puff texturing!

We went to Tanzania over the Christmas/New Year holidays - the first time we had ever gone somewhere hot at that time of year. It was great to see sunshine and all the birds and animals while on safari. Best of all was Zanzibar - the Spice Island - and a dream destination of mine for many years. Hot, noisy, crowded and smelling of exotic spices and other unmentionable things, Zanzibar is unforgettable. The fabrics in the markets were very tempting - I couldn't resist buying one of the Barack Obama pieces that will probably go on the back of a quilt someday. Many of the items for sale in the markets are going to provide inspiration for my quilt making. I love the surface design of these shells. The colours of the chillis were very exciting as were the textures - but let's not talk about how the fish market smelled in 38C/100F degree heat! How about this for a quilting pattern? My favourite part of the trip was a visit to a restaurant called The Rock - check out the website: http://www.therockrestaurantzanzibar.com/ Here is the view from our table - I can just see this image reproduced with hand-dyed fabrics, ripped to provide depth and texture. A final image of some of the amazing fabrics for sale in Stone Town:

|

Archives

March 2023

Categories

All

|

RSS Feed

RSS Feed